ETHYLENE FACT

About Ethylene Gas (C2H4):

Ethylene (C2H2) is an odourless, colourless gas naturally produced and released by fresh fruits and vegetables as a ripening agent.

Ethylene gas is also an ever-present pollutant resulting from exhaust fumes from internal combustion engines (including propane-powered forklifts), improperly vented greenhouse heaters, industrial waste, etc…

Ripening fruit is well known for producing ethylene. However, other plant tissues also produce this gas and can lead to decay and wilting. Even when cut from the growing plant, fruits, vegetables, and flowers are still alive and respiring. Gaseous respiration products of fruits and vegetables, production by normal healthy flower and plant tissue, chopped or damaged leaf tissue, and diseased leaves and tissues can be significant sources of ethylene.

The Role of Ethylene Gas:

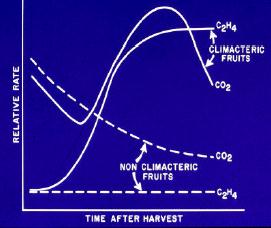

Ethylene, also known as the “ripening hormone” plays a regulatory role in many processes of plant growth, development and senescence/decaying.

Ethylene, also known as the “ripening hormone” plays a regulatory role in many processes of plant growth, development and senescence/decaying.

Fruits, vegetables and flowers contain receptors which serve as bonding sites to absorb ethylene molecules. The common practice of placing a kiwi, avocado or banana in a bag to hasten ripening is an example of the action of ethylene on produce: increased levels of ethylene contained within the bag, released by the produce itself, serve as a stimulant to initiate the production of more ethylene. The overall effect is to hasten ripening, aging and eventually spoilage.

A refrigerator acts in a similar way: while kept closed to retain the desired temperature, it also enables an increased concentration of built-up ethylene. Any closed environment, such as a truck trailer, reefer container, ships hold, or warehouse will have a similar effect.

Why Control Ethylene?

The effects of ethylene gas damage are: shrinkage of fresh produce and flower bulbs; spotting of leafy vegetables; yellowing;; increase odour and sprouting; wilting of vegetables and cut flowers; scald and loss of crunch; and rind breakdown. Controlling ethylene levels preserves freshness.

Within the industry, it is estimated that losses directly related to ethylene run into billions of dollars annually. Removal of ethylene from the storage and shipping environment delays spoilage, reduces loss and increases profit.

Ethylene will penetrate most substances. It will permeate through produce cardboard shipping boxes, wood and even concrete walls.

Ethylene is harmful to many fruits, vegetables, and floral items. While ethylene is invaluable due to its ability to initiate the ripening process in several fruits, it can also be very harmful to many fruits, vegetables, flowers, and plants by accelerating the aging process and decreasing the product quality and shelf life. The degree of damage depends upon the concentration of ethylene, length of exposure time, and product temperature. One of the following methods should be used to ensure that ethylene-sensitive produce is not exposed:

- Ethylene producing items (such as apples, avocados, bananas, melons, peaches, pears, tomatoes…) should be stored separately from ethylene-sensitive ones (broccoli, cabbage, cauliflower, leafy greens, lettuce, etc.). Also, ethylene is emitted by engines. Propane, diesel, and gasoline powered engines all produce ethylene in amounts large enough to cause damage to the ethylene-sensitive produce items mentioned

- Ventilate the storage area, preferably to the outside of the warehouse, on a continuous or regular basis to purge the air of any ethylene.

- Remove ethylene with ethylene absorbing filters. These have been proven in reducing and maintaining low ethylene levels. If ethylene damage is suspected, a quick and easy way to detect ethylene levels is with hand held sensor tubes. This will indicate if the above steps should be followed.

Ethylene has been scientifically proven to cause:

- Increase in respiration

- Water loss/weight loss

- Yellowing or spotting

- Production of more ethylene

- Accelerated ripening, ageing and decay

- Reduction in nutrient content (e.g. loss of vitamin C)

- Taste and aroma changes, off-flavors such as bitterness

- Loss of leaves and flowers, sprouting, toughening

PDF TO DOWNLOAD

Australian Journal of Experimental Agriculture CSIRO

- Importance of low ethylene levels to delay senescence of non-climacteric fruit and vegetables

- Ethylene levels associated with fruit and vegetables during marketing

- Ripening of climacteric fruits initiated at low ethylene levels

University of Newcastle, Australia

- A NEW RATING SCALE FOR ETHYLENE ACTION ON POSTHARVEST FRUIT AND VEGETABLES

- AUSSIE STUDY ETHYLENE LEVEL

Sydney Postharvest Laboratory

Modified Atmosphere Packaging for Fresh Produces

MAP BAG Modified Atmosphere Packaging (MAP) . It uses the gases produced and consumed during the respiration of fresh produce, that is carbon dioxide (CO2) and oxygen (O2) respectively, to produce a favourable atmosphere in a specially designed polymeric film package. a unique atmosphere for that product is created, enriched in CO2 and reduced in O2. This favourable atmosphere slows the metabolic activity of the produce to a very low level, and thus MAP enables the storage of highly perishable produce for prolonged periods.

MAP BAG Modified Atmosphere Packaging (MAP) . It uses the gases produced and consumed during the respiration of fresh produce, that is carbon dioxide (CO2) and oxygen (O2) respectively, to produce a favourable atmosphere in a specially designed polymeric film package. a unique atmosphere for that product is created, enriched in CO2 and reduced in O2. This favourable atmosphere slows the metabolic activity of the produce to a very low level, and thus MAP enables the storage of highly perishable produce for prolonged periods.

The ability to store produce, while retaining its food and nutritional value, increases market flexibility.

Industries can add value to produce, by storing it during market gluts and releasing it when demand increases and by branding and differentiating produce as high quality and high value.

Exporters can use relatively cheap and available Sea freight transport, which increases competitiveness in existing markets and allows access to new markets.

MAP is essential for the successful marketing of these products, which are expected to add up to $1 billion to the value of the Australian vegetable industry.

All fresh produce is alive and must burn up food reserves to keep it alive. The chemical reactions involved are generally termed respiration. In normal healthy plants, respiration involves the uptake of oxygen (O2) by the plant tissue to oxidise food reserves, usually sugars, to produce energy, carbon dioxide (CO2) and water. In simple terms, the energy produced is used to maintain essential life processes, while the CO2 and some of the water are ‘waste’ products and are released to the surrounding environment.

When fresh produce is sealed inside a map bag, respiration will lower the in-package O2 level and increase the CO2 level. A major challenge in designing MA packages, is to match the rate of O2 uptake and CO2 production of the produce, with the O2 and C02 permeability of the package. Gas levels inside the package will equilibrate within a range which benefits the produce.

Optimum CO2 and O2 concentrations are product specific and vary enormously between products. It should be noted that exact recommendations are rare and often a therapeutic range is quoted, as optimum gas levels can vary according to cultivar or genotype, production area, harvest maturity and several other factors.

When optimum atmosphere for a product is achieved, its storage life can be increased by many times that which can be expected using conventional refrigerated air storage. Elevated CO2 and reduced O2 levels slow quality loss in several ways. The principal effect is usually considered to be in suppressing respiratory activity

The post-harvest life of fresh horticultural produce is inversely proportional to its storage life. That is, the lower the respiration rate, the longer food reserves are conserved, and the longer life processes can be maintained. This effect is often termed ‘putting the produce to sleep’. However, there are several other benefits. High CO2 and low O2 atmospheres can:

- Block the mode of action and biosynthesis of ethylene, a ubiquitous plant hormone which promotes aging and senescence.

- Reduce rots by directly inhibiting the growth of pathogens and by maintaining the health and integrity of the plant tissue, which reduces its susceptibility to infection.

- Slow yellowing of green tissues by preventing chlorophyll degradation

- Maintain the food and nutritional value and flavour of produce by slowing the loss of food reserves, particularly sugars, inhibiting the loss of labile vitamins such as vitamins C and A, and by slowing the accumulation of undesirable secondary metabolites in the plant’s tissues, such as free ammonia.

- Slow cell membrane degradation and loss of cellular compartmentation and function.

- Inhibit discoloration of cut surfaces.

MA/MH package provide significant benefits to fresh produce in reducing quality loss and extending storage and market life. MAP provides the horticultural industry with a means to add value to their crops by expanding existing and developing new domestic and export markets.

The Minister for Primary Industries, Mr Simon Crean, stated that the development of MAP will add $300 million per annum to the value of Australian horticultural exports.